Page 1 of 1

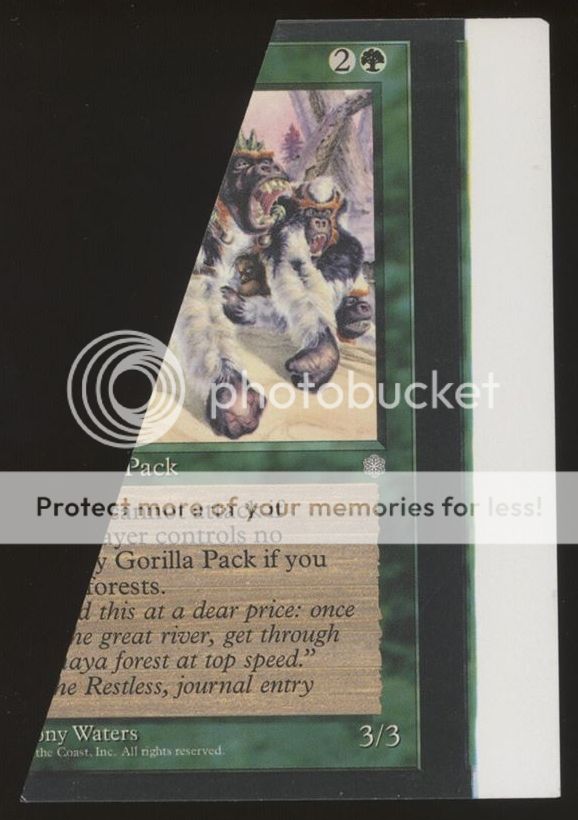

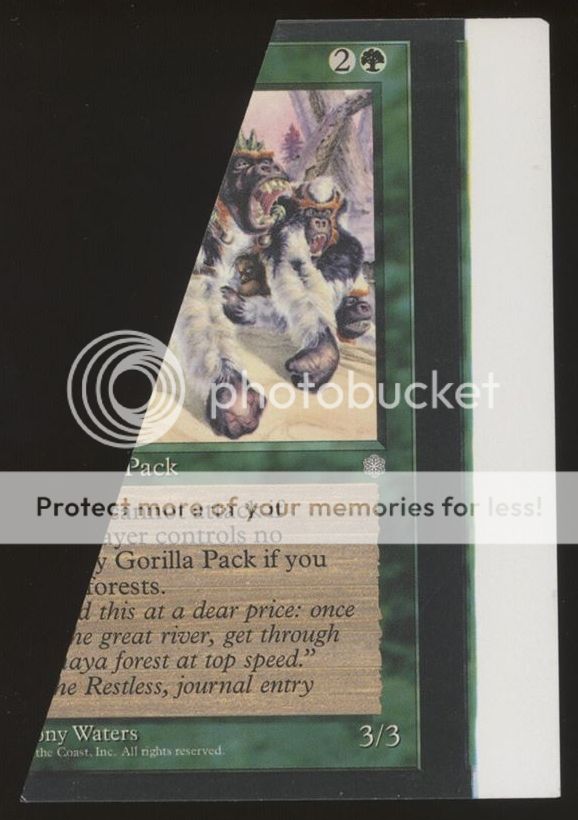

What went wrong with these 3 Misprints ?

Posted: Mon Oct 14, 2013 7:05 am

by dragsamou

Posted: Mon Oct 14, 2013 7:26 pm

by hammr7

The first batch of misprints look like they are the proper size for cards, so I would expect the sheet was used to get the sheet guides - which controls sheet feed the way a laser or ink jet printer guide controls paper feed - set up correctly. They may have then been run through the corner trimmer.

When printing sheets, at every process step there is usually some scrap generated as the process is "dialed in" to the proper specification. When Magic first came out, Magic cards were only a small part of Carta Mundi's output. They didn't have dedicated machines to process Magic cards (like they probably have now). So they had to set their equipment to WOTC specifications for each batch of cards they ran.

Usually, such start-up sheets are immediately scrapped (total scrap, from all process steps, is as much as 1% to 5% of the total production run). For a run of 10,000 sheets, 100 or more may be scrapped. Those cards from the start up were never supposed to leave the printing facility.

The second piece may have been hand cut or may have been jammed in the cutting machine. Every sheet of cards generates edge scrap. That the piece is cut weird makes me think the sheet was hand cut (perhaps as a color match sample).

In cold, dry weather, given the large number of rollers along the printing / trimming / packaging process, you can build up a decent amount of static electricity. Every once in a while a trim or scrap piece of card stock may cling to a regular card. If that piece of scrap stuck to a card, it could have ended up in a package. Or it may have walked out the door some other way.

The third error was likely caused either by a dulled cutting edge or by the sheet popping a bit out of the sheet guides at the cutting station. The knife edge, instead of making a clean cut, either pushed the sheet a bit to the side or had the knife edge pushed a bit to the side in the middle of the cut. Knife edges dull and need to be replaced. The first indication is usually ragged cuts. Usually the process is stopped, the knife edges replaced, and any "bad" product scrapped. sometimes the machine operator doesn't catch the minimally "bad" product.

Posted: Tue Oct 15, 2013 7:17 am

by dragsamou

hammr7 wrote:The first batch of misprints look like they are the proper size for cards, so I would expect the sheet was used to get the sheet guides - which controls sheet feed the way a laser or ink jet printer guide controls paper feed - set up correctly. They may have then been run through the corner trimmer.

When printing sheets, at every process step there is usually some scrap generated as the process is "dialed in" to the proper specification. When Magic first came out, Magic cards were only a small part of Carta Mundi's output. They didn't have dedicated machines to process Magic cards (like they probably have now). So they had to set their equipment to WOTC specifications for each batch of cards they ran.

Usually, such start-up sheets are immediately scrapped (total scrap, from all process steps, is as much as 1% to 5% of the total production run). For a run of 10,000 sheets, 100 or more may be scrapped. Those cards from the start up were never supposed to leave the printing facility.

The second piece may have been hand cut or may have been jammed in the cutting machine. Every sheet of cards generates edge scrap. That the piece is cut weird makes me think the sheet was hand cut (perhaps as a color match sample).

In cold, dry weather, given the large number of rollers along the printing / trimming / packaging process, you can build up a decent amount of static electricity. Every once in a while a trim or scrap piece of card stock may cling to a regular card. If that piece of scrap stuck to a card, it could have ended up in a package. Or it may have walked out the door some other way.

The third error was likely caused either by a dulled cutting edge or by the sheet popping a bit out of the sheet guides at the cutting station. The knife edge, instead of making a clean cut, either pushed the sheet a bit to the side or had the knife edge pushed a bit to the side in the middle of the cut. Knife edges dull and need to be replaced. The first indication is usually ragged cuts. Usually the process is stopped, the knife edges replaced, and any "bad" product scrapped. sometimes the machine operator doesn't catch the minimally "bad" product.

Hi Hank

Brilliant as usual. Regarding the second piece, I have opened the booster myself

I have bought also 2 pieces like that from Famous MTG shops in the US, when I asked about them, the answer was always the same, while opening Boosters, we just find those and by looking around, I have noticed at least, 10 different ones with different degrees of miscuting. Adding scans of some Extreme Miscut that I found (NFC or Factory Cut ?)